why cedar

Back

why use western red cedar?

characteristics & properties of western red cedar

benefits of real cedar

real cedar history

real cedar certification

sustainability & the environment

biophilia

forestry facts

why use yellow cedar?

products

Back

siding

Back

introduction

Back

siding home

siding gallery

virtual siding samples

siding installation videos

design & spec

Back

siding grades

engineered cedar

siding calculator

prep & install

Back

preparation

pre-building

tyvek drainwrap

general installation

finish & maintain

Back

choosing a finish

how to finish

care & maintenance

restoration

siding profiles & trim

Back

bevel

trim boards

board & batten

shingle panels

tongue & groove

lap or channel

soffits and entryways

decking

Back

introduction

Back

decking home

decking gallery

virtual decking samples

design & spec

Back

decking grades

decking span charts

span tables

decking calculator

prep & install

Back

fasteners

stairs & railings

finish & maintain

Back

choosing a finish

how to finish

care & maintenance

restoration

deck projects

Back

roof deck

ground level deck

raised deck

uphill sloping lot deck

outdoor

Back

introduction

Back

outdoor home

outdoor gallery

design & spec

Back

diy plans

pre-built kits

design tips

span tables

prep & install

Back

preparation

fasteners

finish & maintain

Back

choosing a finish

how to finish

care & maintenance

restoration

fencing

Back

fencing home

fence construction

fence specifications

pre-built fence panels

indoor

Back

introduction

Back

indoor home

indoor gallery

design & spec

Back

design tips

prep & install

Back

preparation

finish & maintain

Back

how to finish

care & maintenance

indoor projects

Back

saunas

doors & windows

tongue & groove paneling

blinds & shutters

timbers

Back

introduction

Back

timbers home

timbers gallery

virtual timber samples

design & spec

Back

grades & specs

engineered cedar

span tables

prep & install

Back

preparation

installation

finish & maintain

Back

how to finish

care & maintenance

restoration

diy projects

membership

Back

our members

Back

executive members

retailers

partners

tertiary manufacturers

certified cedar distributors

certified cedar distributors – usa

certified cedar distributor – canada

architects

international associates

why become a member?

membership levels

membership benefits

membership faq

join the wrcla!

member support

resources

Back

real cedar resources

blog

gallery

videos

cedar books

|

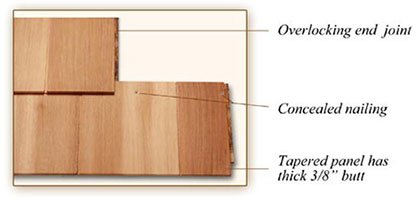

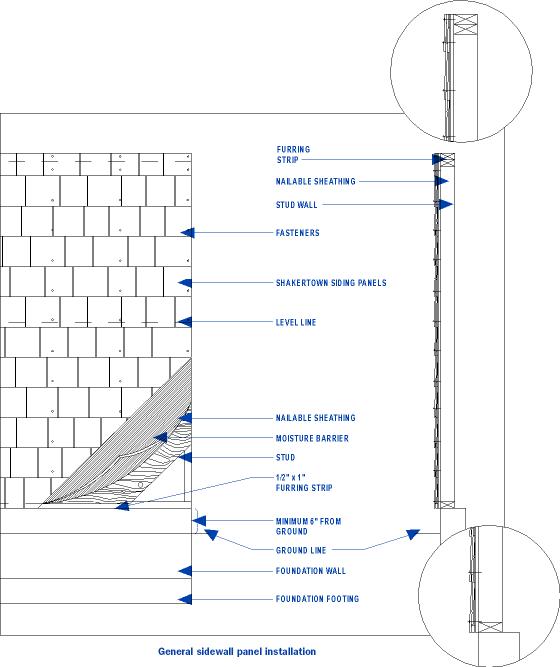

Installing Shingle Panels

Preparation

Clean surfaces thoroughly prior to installation.

Clean surfaces thoroughly prior to installation.- Prepare surfaces using the methods recommended by the manufacturer for achieving the best result for the substrate under the project conditions.

- Determine prior to framing layout which corner treatment is to be utilized. Panels require a nailable area 5-1/4 inches (133 mm) of outside corners and 3-1/2 inches (89 mm) of inside corners.

- After framing is completed, install building paper horizontally, shingle style, beginning at bottom of wall with 3 inches (76 mm) overlaps.

- Corner boards, trim and molding:

- Shall be extended a minimum 1 inch (25.4 mm) from sheathing to allow for 7/8 inch (22 mm) depth of applied shingle panels.

Installation

Install in accordance with manufacturer’s instructions.

Install in accordance with manufacturer’s instructions.

- Install shingle panels by attaching to solid nailable sheathing, spaced nailable sheathing or to studs.

- Install working from the lowest level up to the top of the wall area

- Furr out the bottom course of siding with 3/8 inch by 1 inch (9.5 by 25.4 mm) wood strips. Allow for canting of the first course of siding and install to level line.

- Drive nails flush with siding surface, penetrating studs at least 1/2 inch (12.7 mm).

- Maintain 1/8 inch (3 mm) spacing at corner boards and trim. Caulk with non-hardening sealant.

- Maintain 1/16 inch (1.6 mm) spacing between ends of panels in order to allow for natural expansion.

- Maintain 1/4 inch (6 mm) space from panel butt line and flashing.

You

Cedar as much as we do?

© 2026 All rights reserved

Gatsby Website Development by Jambaree